Textile Motorcycle Jacket Manufacturer for Mass Production, OEM, and Private Label Brands

In the global motorcycle apparel industry, selecting the right Textile Motorcycle Jacket Manufacturer is one of the most important strategic decisions a brand can make. Textile motorcycle jackets are technical garments that must perform under real riding conditions while also meeting commercial requirements such as scalability, consistency, and international compliance. For OEM and private label brands, manufacturing reliability directly affects product quality, delivery timelines, and long-term brand reputation.

As markets become more competitive, motorcycle apparel brands increasingly seek manufacturing partners that specialize in bulk production rather than general garment manufacturing. This is where a dedicated production specialist adds significant value. From fabric selection and product development to mass production and export readiness, every stage of manufacturing must be structured, repeatable, and quality-driven.

Maxler Motosport operates as a B2B-focused Textile Motorcycle Jacket Manufacturer, working exclusively with OEM and private label clients that require bulk, export-ready production. This article provides an in-depth look at how professional textile motorcycle jacket manufacturing works, what brands should expect from a reliable production partner, and how structured manufacturing supports long-term growth.

Maxler Motosport

The Role of a Textile Motorcycle Jacket Manufacturer in the Motorcycle Apparel Industry

A professional Textile Motorcycle Jacket Manufacturer plays a central role in transforming design concepts into durable, market-ready products. Unlike fashion apparel, motorcycle jackets are performance garments that must balance protection, comfort, and durability. Manufacturing decisions directly influence how a jacket performs over time, especially under repeated riding conditions.

Motorcycle jackets must accommodate riding posture, exposure to wind, abrasion risks, and long hours of use. A specialized manufacturing partner understands these functional requirements and applies them during pattern development, construction planning, and material selection. This technical understanding separates motorcycle apparel manufacturing specialists from general textile factories.

At Maxler Motosport, production workflows are designed specifically for motorcycle jackets. As an experienced Textile Motorcycle Jacket Manufacturer, the focus remains on technical construction standards rather than fashion-driven shortcuts. This ensures that jackets produced in bulk maintain consistent performance across all units.

Why Brands Choose a Specialized Manufacturing Partner

Motorcycle apparel brands that rely on non-specialized garment factories often encounter issues such as inconsistent sizing, weak seam construction, or unreliable material sourcing. These challenges become more pronounced at scale. A specialized Textile Motorcycle Jacket Manufacturer minimizes these risks through structured processes built specifically for motorcycle apparel production.

Brands choose manufacturers like Maxler Motosport because specialization allows for better control over every production variable. From reinforced stitching zones to ventilation panel placement, a dedicated motorcycle apparel manufacturer applies industry-specific knowledge that general apparel factories lack.

This specialization is especially important for brands targeting international markets, where buyers expect consistent quality across large order volumes.

Mass Production as a Core Manufacturing Capability

Mass production is not simply about producing high quantities. For a Textile Motorcycle Jacket Manufacturer, mass production is about repeatability, control, and efficiency. International brands depend on consistent product quality across hundreds or thousands of jackets, often across multiple production cycles.

A structured mass production system allows manufacturing teams to standardize materials, workflows, and quality benchmarks. At Maxler Motosport, production capacity is designed to support bulk orders while maintaining uniform construction standards. This approach allows brands to scale confidently without sacrificing product integrity.

Mass production also supports cost efficiency. When production processes are optimized and repeatable, manufacturers can reduce waste, improve labor efficiency, and stabilize pricing for long-term partners.

Product Development and Technical Preparation Before Bulk Manufacturing

Before bulk production begins, a professional manufacturing partner must establish clear technical foundations. Product development involves translating design concepts into precise production specifications that can be accurately repeated at scale.

At Maxler Motosport, this stage includes pattern engineering, size grading, construction planning, and workflow preparation. As a trusted Textile Motorcycle Jacket Manufacturer, the company emphasizes pre-production accuracy to reduce errors and ensure smooth manufacturing execution.

Fabric Selection and Material Planning in Textile Motorcycle Jacket Manufacturing

Fabric selection plays a critical role in textile motorcycle jacket performance. A professional Textile Motorcycle Jacket Manufacturer must balance abrasion resistance, breathability, comfort, and durability while ensuring materials remain suitable for large-scale production.

For international markets, textile motorcycle jackets are commonly designed to align with recognized safety and performance frameworks such as CE-rated protective standards, which define impact and abrasion testing benchmarks used across the motorcycle apparel industry.

CE-rated protective standards:

https://www.motorcyclecouncil.org/ce-certification/

Maxler Motosport prioritizes material consistency to support repeat orders, allowing the company to operate as a dependable manufacturing partner for long-term product lines.

Inside the Mass Production Process

The production workflow follows a structured sequence. Bulk cutting is performed using standardized patterns to maintain size accuracy. Assembly lines are divided into defined stages, with skilled operators assigned to specific construction tasks.

At Maxler Motosport, this disciplined workflow ensures consistent stitching quality, reinforced stress areas, and uniform finishing. Such operational structure is essential for manufacturers producing for international motorcycle apparel brands.

Quality Control Systems in Bulk Textile Motorcycle Jacket Production

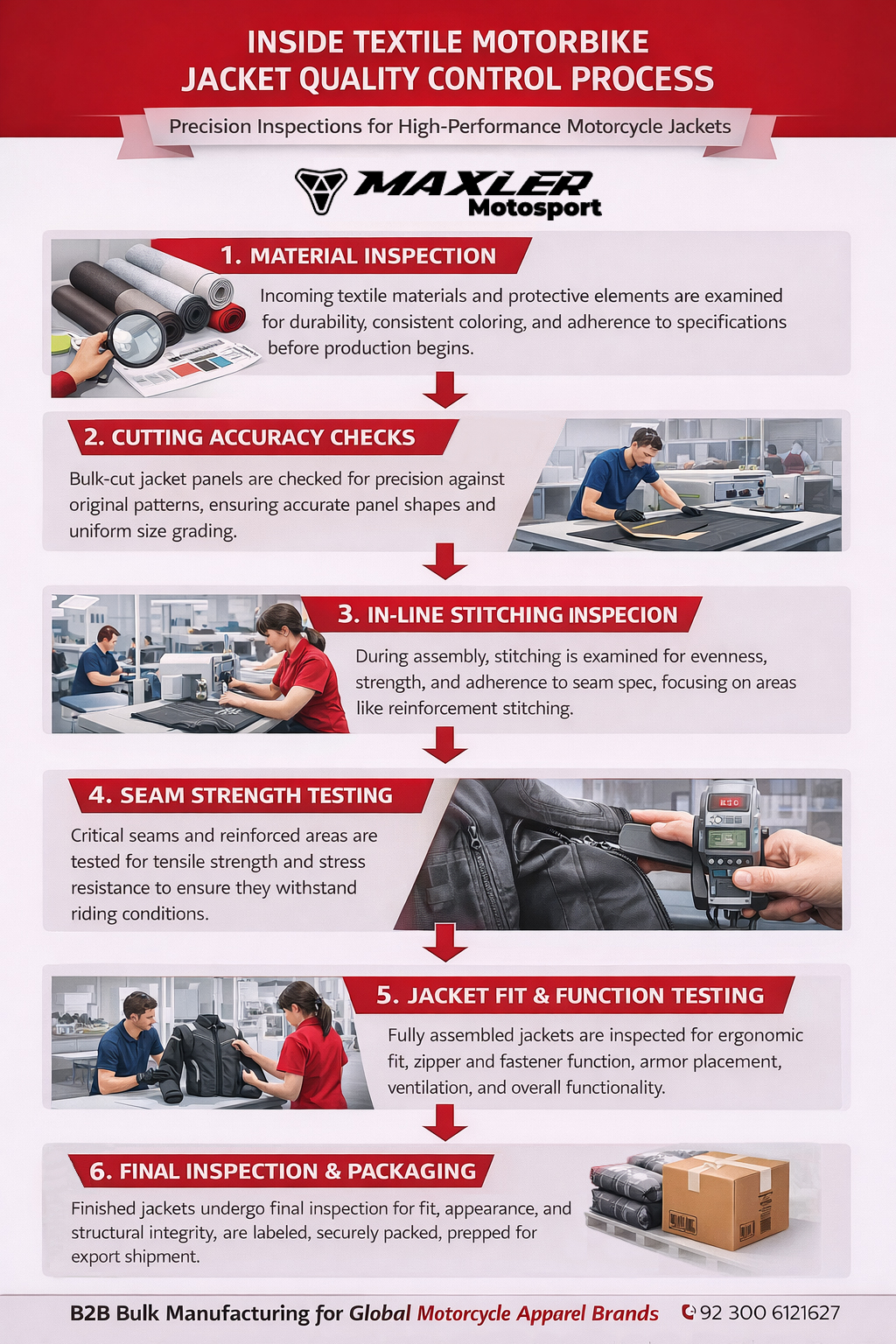

Quality control is an ongoing process rather than a final checkpoint. A reliable Textile Motorcycle Jacket Manufacturer integrates inspections at multiple stages of production to identify and correct issues early.

Maxler Motosport applies in-line inspections, construction checks, and final quality verification before packaging. This layered quality control system supports repeat orders where consistency is essential.

OEM and Private Label Manufacturing Perspective

OEM and private label manufacturing models enable brands to build unique product identities while relying on a Textile Motorcycle Jacket Manufacturer for technical execution. Under these arrangements, manufacturers handle materials, construction, and quality management based on brand-defined specifications.

Maxler Motosport works closely with OEM and private label clients to ensure production requirements are clearly defined and consistently applied. This collaborative approach allows customized products to be delivered at scale while maintaining operational efficiency.

Scalability, Repeat Orders, and Long-Term Manufacturing Partnerships

Scalability is a defining advantage of working with an experienced Textile Motorcycle Jacket Manufacturer. Once a jacket style is approved, repeat orders can be produced using the same patterns, materials, and workflows, resulting in reduced lead times and stable quality.

Maxler Motosport supports long-term partnerships by maintaining production continuity and documentation for approved styles. This allows the company to operate as a strategic manufacturing partner rather than a short-term supplier.

Export-Ready Manufacturing and International Market Expectations

A Textile Motorcycle Jacket Manufacturer serving international clients must align production processes with export requirements. This includes regional size grading, packaging standards, and buyer compliance expectations.

Maxler Motosport structures its operations to support export-ready manufacturing, enabling brands to distribute textile motorcycle jackets across Europe, North America, and other global regions.

Why Brands Partner With Maxler Motosport

Brands choose Maxler Motosport because it operates as a specialized, B2B-only Textile Motorcycle Jacket Manufacturer. By focusing exclusively on bulk production, OEM services, and private label manufacturing, Maxler Motosport offers reliability, consistency, and manufacturing maturity.

Rather than functioning as a general garment supplier, Maxler Motosport positions itself as a long-term manufacturing partner for motorcycle apparel brands seeking scalable production and dependable quality.

Conclusion

The success of motorcycle apparel brands depends heavily on the capabilities of their manufacturing partners. A professional Textile Motorcycle Jacket Manufacturer provides structured production systems, technical expertise, and quality assurance that support sustainable growth.

By working with an experienced Textile Motorcycle Jacket Manufacturer like Maxler Motosport, OEM and private label brands gain access to export-ready manufacturing solutions designed for long-term success in international markets.