Description

Manufactured by a Professional OEM textile motorcycle jacket Supplier

The ASPAR Textile Summer Jacket is a warm-weather motorcycle garment developed for brands that require consistent quality, lightweight construction, and dependable OEM manufacturing support. Designed and produced by Maxler Motosport, this OEM textile motorcycle jacket is engineered for private label, bulk, and long-term sourcing programs serving international motorcycle apparel markets.

In the competitive motorcycle apparel industry, working with an experienced OEM textile motorcycle jacket supplier ensures production stability, repeatable quality, and controlled manufacturing processes. The ASPAR jacket is purpose-built for summer riding conditions and professional B2B supply rather than short-term retail fashion.

Manufacturing Expertise at Maxler Motosport

Maxler Motosport operates as a Pakistan-based manufacturer specializing in technical motorcycle apparel for global brands. The ASPAR OEM textile motorcycle jacket is produced using lightweight yet durable textile materials selected to perform reliably in high-temperature riding environments.

Fabric sourcing, pattern engineering, cutting, stitching, finishing, and inspection are handled under structured factory systems. This integrated approach allows Maxler Motosport to maintain consistent quality across bulk orders and repeat production cycles, which is essential for OEM programs.

Lightweight Construction for Summer Riding Conditions

The ASPAR Textile Summer Jacket is engineered to deliver airflow and rider comfort during extended summer use. Lightweight textile panels help reduce heat buildup while maintaining the durability required for motorcycle apparel.

Ventilation zones are integrated into the design to enhance breathability, while reinforced sections maintain structural integrity in key stress areas. This balance allows brands to confidently offer a summer-focused OEM textile motorcycle jacket suitable for urban commuting, touring, and daily riding.

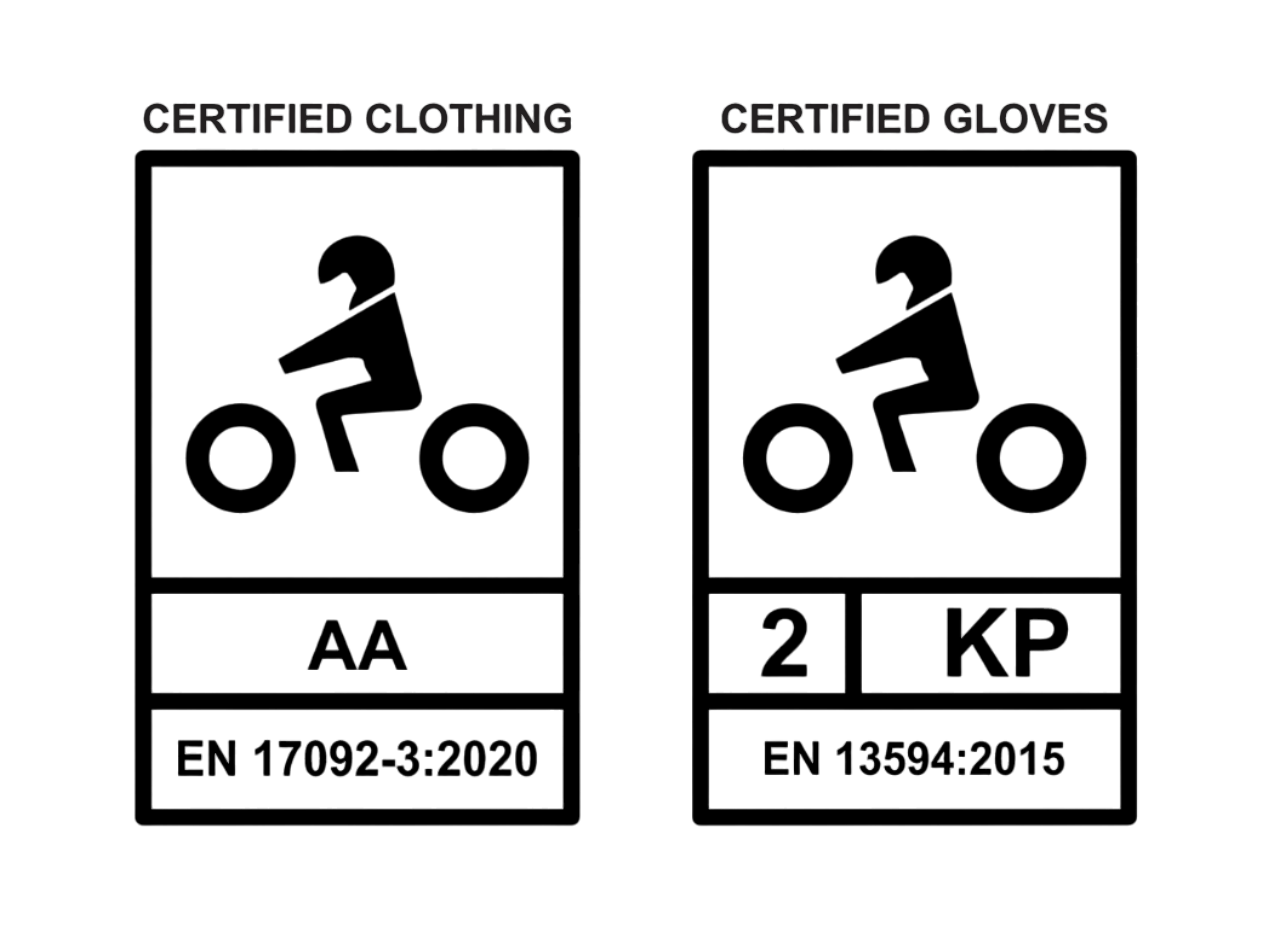

CE-Ready Protection Compatibility

Protection readiness is an essential requirement for modern motorcycle apparel. The ASPAR OEM textile motorcycle jacket is designed with CE-ready armor pockets at impact-critical areas such as shoulders, elbows, and the back. This enables brands to integrate approved protection systems according to their target market requirements.

Understanding CE protection standards is important for sourcing decisions, and this industry resource explains how armor ratings influence compliance and safety expectations:

https://www.d3o.com/d3o-insights/motorcycle-armor-ce-certification/

Designing the ASPAR jacket with protection compatibility supports certification readiness and buyer confidence in regulated markets.

Bulk Production and Manufacturing Scalability

Scalability is a key advantage of working with a professional OEM manufacturer. The ASPAR OEM textile motorcycle jacket is optimized for bulk production with consistent materials, accurate sizing, and uniform construction across large manufacturing volumes.

Maxler Motosport follows a structured production workflow that includes pre-production sampling, fabric inspection, in-line quality control, and final inspection prior to shipment. This process minimizes production risks and ensures predictable lead times for brands managing seasonal inventory.

For a detailed overview of how structured jacket production supports OEM growth, our manufacturing process is outlined here:

https://maxlermotosport.com/textile-motorcycle-jacket-manufacturer/

Custom Branding and OEM Development Support

As a full-service OEM partner, Maxler Motosport provides complete private label and branding support. The ASPAR jacket can be customized with brand logos, interior labels, color specifications, hardware selection, and market-specific sizing.

Custom samples with client branding are produced prior to mass production, allowing buyers to approve fit, materials, and branding details in advance. This reduces revision risks and ensures long-term consistency across future OEM production cycles.

Serving Motorcycle Apparel Brands in the USA, Europe, and Australia

As a Pakistan-based manufacturer, Maxler Motosport supplies this OEM textile motorcycle jacket for motorcycle apparel brands in the USA, across Europe, and in Australia. Our export-focused manufacturing systems are aligned with international compliance expectations and long-term bulk supply requirements.

This exporter-oriented approach allows brands to source globally while maintaining transparency regarding manufacturing origin and quality standards.

Export-Ready Manufacturing from Pakistan

Pakistan is globally recognized for technical motorcycle apparel manufacturing. Partnering with Maxler Motosport provides access to skilled labor, competitive production costs, and export-ready infrastructure.

Our operations support international documentation, packaging standards, and logistics coordination for global shipments, making the ASPAR jacket suitable for long-term international supply programs.

Quality Assurance and One-Year Replacement Warranty

Quality assurance is a core principle at Maxler Motosport. Each ASPAR OEM textile motorcycle jacket is produced under controlled quality systems to ensure consistent workmanship across bulk orders.

To support buyer confidence, a one-year replacement warranty covering manufacturing defects is provided. This warranty reflects the reliability expected from a professional OEM manufacturing partner and supports long-term sourcing relationships.

Why Choose Maxler Motosport for OEM textile motorcycle jacket Manufacturing

The ASPAR Textile Summer Jacket demonstrates what professional motorcycle apparel brands expect from a dependable OEM manufacturing partner. Lightweight summer construction, CE-ready protection compatibility, private label flexibility, scalable bulk production, and export-ready manufacturing are all integrated into this product.

By partnering with Maxler Motosport, brands gain access to a reliable manufacturer capable of delivering consistent quality and supporting sustainable growth through repeat OEM production cycles.